In Water Cooling , Water is used for cooling the engine by circulating it through water jackets around each combustion chamber cylinder, cylinder head, valve and valve sheet. By absorbing heat, water will become hot. When it is again passed through radiator, it will be cooled by air blast due to forward motion of the vehicle as well as of this engine to absorb heat.

These are two systems of water-cooling.

1. Thermosyphon System.

2. Pump Circulation System.

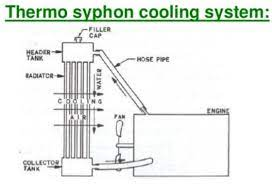

I) THERMOSYPHON SYSTEM :

The principle of hot water going up and cold water coming down due to difference in density is used here. There is no pump to circulate water. The light hot water from the engine goes to the top of the radiator by itself and gets cooled by the surrounding air and hence goes down to bottom of radiator and again goes to engine cylinder.

It is simple, cheap but cooling is slow. Water should be maintained to correct level at all time.

II) PUMP CIRCULATION SYSTEM :

To make Thermosyphon system more effective and improve water circulation , a water pump is introduced which is driven by a v-belt from a pulley on the engine crank shaft. This is called pump circulation system.

The water - cooling arrangement for a 4 cylinder engine. When the hot water in engine passes through radiator tubes from the upper tank to lower tank, it is exposed to large amount of airflow and gets sufficiently cooled. Then it is pumped to cylinder jackets by the water pump. The automatic thermostatic valve is used to regulate the circulation of water so that very cold water will become hot in short time to improve efficiency of the engine.

Comments

Post a Comment